- Servo motor arduino code 360 degrees serial#

- Servo motor arduino code 360 degrees full#

- Servo motor arduino code 360 degrees software#

In some circumstances, when the servos and processor are running off the same power supply, the servos can draw so much current (or put so much noise on the line) that it may cause your processor to reset or misbehave.They might also audibly hum, or repeatedly reset. Underpowered servos are prone to hunting, where they don't move cleanly to the desired position, but instead move back and forth near that position.They'll move more slowly than a properly powered servo. When the power supply isn't up to the task, servos behave poorly.

Servo motor arduino code 360 degrees full#

For full strength, you should be sure that your power supply can provide at least one Ampere per servo.

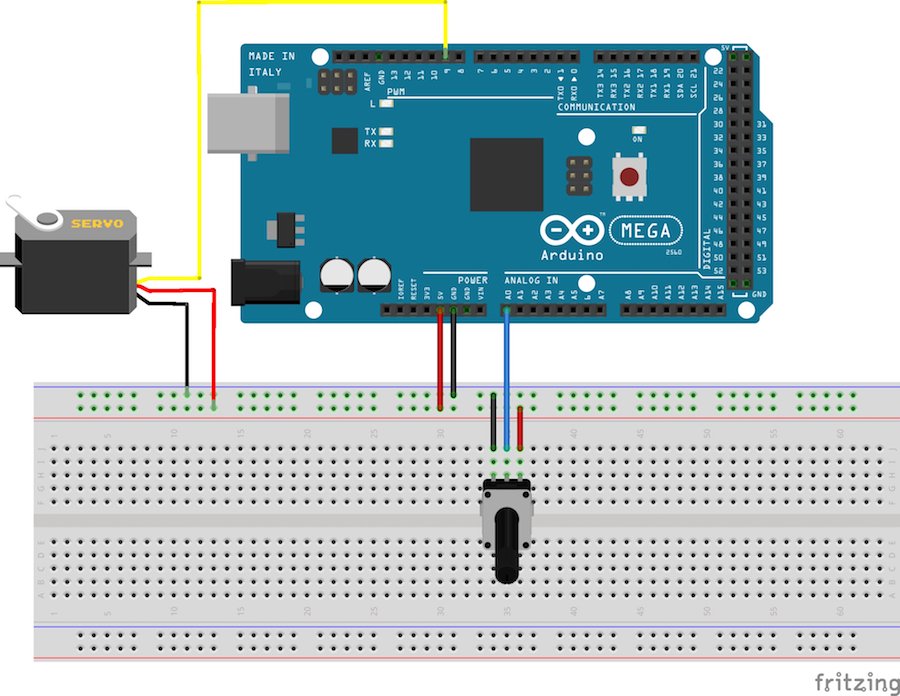

Even unloaded servos can draw quite a bit of power.Regardless of how you're driving it, servos sometimes require a little extra attention to get working. As noted in the Range Constraints section above, driving a servo outside that range may damage the servo. It is using the optional min and max parameters, to constrain the pulses to the 1000 to 2000 microsecond (1 to 2 millisecond) range. Pay particular attention to the attach() call on line 26. This sketch drives the servo back and forth. Be careful with shorter or longer pulses.

Servo motor arduino code 360 degrees software#

**SparkFun code, firmware, and software is released under the MIT License().** If this is your first time using Arduino, please review our tutorial on installing the Arduino IDE.If you have not previously installed an Arduino library, please check out our installation guide. Note: This example assumes you are using the latest version of the Arduino IDE on your desktop. The old adage rings true: you get what you pay for. Plastic gears are more likely to strip if the motor is jammed or overloaded. Inexpensive servos (such as the one dismantled here) usually contain molded plastic gears, while more expensive servos have metal gears. One last thing to look at when considering a servo is the type of gears it contains.

Servo motor arduino code 360 degrees serial#

There are also digitally-controlled servos that use a high-speed pulse train, and have a serial communication interface that allows more detailed configuration, typically with parameters that are tailored to RC vehicles. The pulse-controlled servos we're discussing here are analog. Shorter pulses will cause it to turn counterclockwise, and longer pulses cause it to turn clockwise. It's typically set so that a 1.5 mSec pulse stops the motor. On closer inspection, continuous rotation servos have one small difference from regular servos: they usually have a "nulling" trimpot, used to adjust their response to the control signal. This configuration is commonly known as “star power.” If one servo causes the power rail to droop, it's less likely to effect the others when each has a direct connection. A small servo with nothing attached to the shaft might draw 10 mA, while a large one turning a heavy lever might draw an Ampere or more! If your power supply isn't up to the task, a straining or stalled servo can cause the supply to sag, which may have other unpredictable repercussions, such as causing microcontrollers to reset.Īdditionally, if you've got multiple servos, or in applications where the motors are moving non-trivial loads, it’s best to use heavy gauge wires and give each servo a direct connection to the power supply, rather than daisy-chaining power from one to the next. Regardless of how you're powering them, it's worth noting that the current consumed by the motor increases as the mechanical loading increases. If you're using an Arduino or other microcontroller (such as the SparkFun Servo Trigger) to control your motor, the absolute maximum supply voltage that should be applied is 5.5 VDC. If you're not using batteries, the 5VDC available from a garden variety power supply is a good option. It starts to feel sluggish just before it dies. As the voltage drops, the available torque also drops - if you've driven RC vehicles, you're no doubt familiar with the loss of control that occurs as the batteries get weaker. It will be somewhat higher after a charge, and it will droop as the batteries discharge. In RC vehicles, the nominal battery voltage is 4.8V.

0 kommentar(er)

0 kommentar(er)